Frequently Asked Questions

Depending on the system, a line of sight is usually necessary to achieve the maximum range. Even without a direct line of sight, BWI Eagle 2.4GHz or 900MHz RF industrial remote control systems achieve a longer operating range than most competitive systems.

The operating range will vary based on various factors, including the transmitting power, the transmitter, the orientation of the receiver, the transmitting antenna’s height, the receiving antenna’s height, weather conditions and terrain. Other sources of interference include indoor and outdoor structures such as walls, metal objects, trees, buildings, hills and mountains.

RF signals can go around or penetrate many obstacles, and different materials have varying effects. For instance, glass, wood and drywall have little impact on distance. Brick and block are more challenging, and solid metal is nearly impossible to get through. Vegetation and ground absorb the RF as much as 50% when transmitted through heavy vegetation.

There are several ways to overcome obstacles that affect the operating range. A combination of these options may be needed to achieve the desired distance.

- Add strategically placed external high-gain antennas .

- Add a repeater between the transmitter and receiver .

- Choose a system with a higher range. Air-Eagle XLT Plus systems can reach up to 10 miles.

The default standard relay mode is maintained momentarily for most BWI Eagle systems. All systems can be custom-programmed with varying relay modes.

Maintained Momentary

This is the default relay operation in our systems. In this mode, the relay is energized when the corresponding button is pressed or the contact input is closed. The relay will de-energize when the button is released or the input opens.

Toggle Latching

A single button on the transmitter controls this relay mode. The relay changes and holds its state each time the button is momentarily depressed. If a user presses and releases once, the relay is energized and latched closed. Press and release a second time, and the relay de-energizes and remains de-energized until the button is depressed again. This mode is only recommended if it is apparent to the user what state the relay is in to avoid the risk of human error.

Latching

Two separate buttons control the latching relay mode. Momentarily pressing Button 1 energizes and latches the relay. Momentarily pressing Button 2 de-energizes the relay.

Additional Relay Modes

- On/Off Delay Timers

- Dual Activation

- Timed Activation

- Disabled Relay

- Passcode Required

If the frequency of all units operating together is the same, an unlimited number of transmitters can communicate with the receiver. You can also have different types of transmitters, handheld or stationary, talking to the receiver.

Confusing the operating frequency with the RF channels is a common misunderstanding. When using a four-button transmitter with a four-relay receiver, each button sends a different RF channel code, but the units operate on the same frequency. Frequency is a consideration when a second system is added in the same vicinity as an existing system, and you wish to have no interference between the two systems.

Air-Eagle products have eight operating frequencies. Systems are shipped from the factory at the first default frequency. Additional programming is only necessary when adding transmitters to an existing system if the default frequency is changed during installation. Programming changes may be needed if the system you add units to has a different frequency.

BWI Eagle systems can control multiple pieces of equipment simultaneously or independently based on how the receivers are wired. Programming support is available through Cattron’s engineering team.

Here are some examples of how a system could be designed to fit specific applications.

- The need is to use one button on a single transmitter to turn four lights on and off simultaneously. The lights are located at different locations in a facility. Four single relay receivers and one single button transmitter are needed. The receivers, by default, respond to button one command from the transmitter. Each light should be wired to the single relay in the receiver, and when button one on the transmitter is pressed, the relay in all four receivers will simultaneously energize at once, turning all the lights on or off.

- The need is to turn four lights on and off in a facility separately. The lights are located at different locations in a facility. A four-button transmitter and four four-relay receivers are needed. Each relay responds to the corresponding button on the transmitter. Wiring light one to relay one in the first receiver, light two to relay two in the second receiver, light three to relay three in the third receiver and light four to relay four in the fourth receiver enables the user to turn each light on independently with a press of the button.

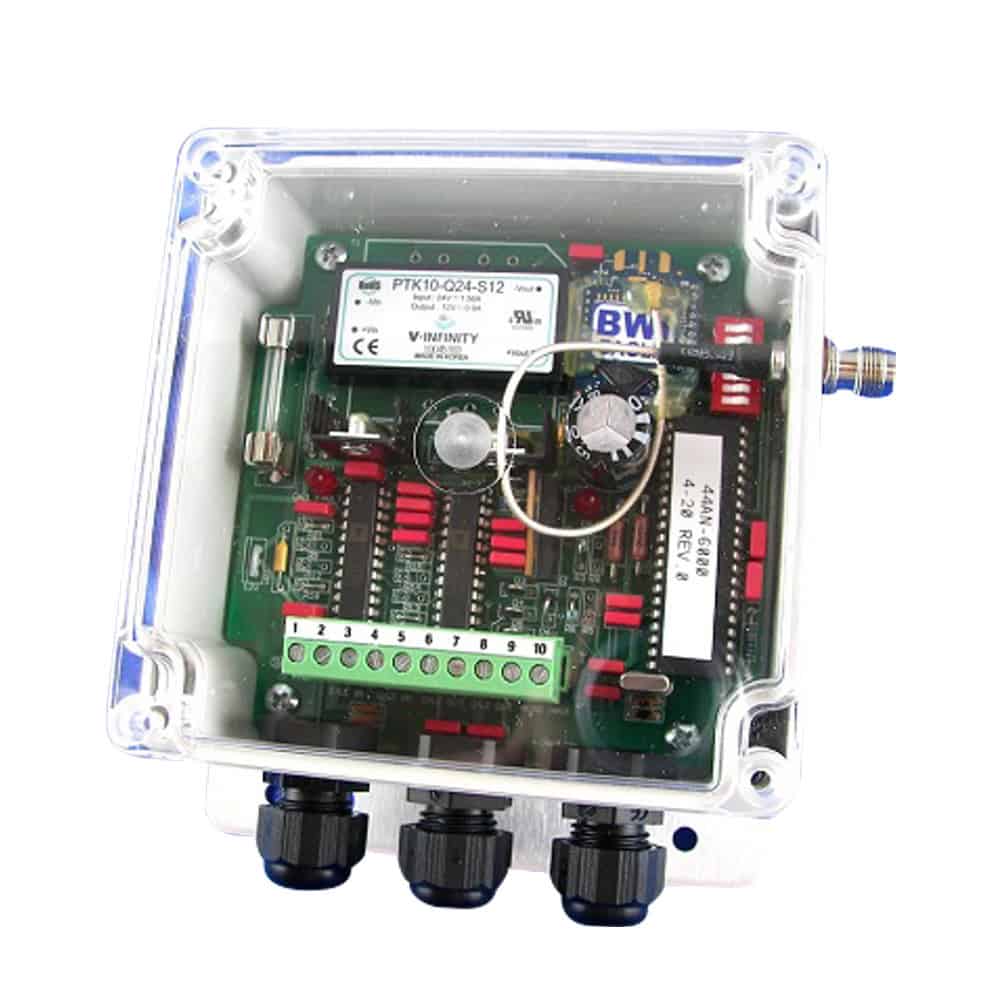

Stationary transmitters allow signals to be triggered by a dry contact input device, such as an external switch, relay or PLC. The transmission occurs automatically when there is a closure on the input. Contact input transmitters are available with one, four, eight or twenty independent channels. For applications that require voltage as a trigger, the units are modified to accept either 120VAC or 5-24VDC to the terminal strip. The transmission is sent when the voltage appears across the input.

Stationary units can be customized to include manual controls for some or all channels. That gives an option for manual control when there is concern that a handheld transmitter may be too easily lost or destroyed. A 120VAC, 9-36VDC or internal battery can power contact and voltage input transmitters. They come equipped with a portable TNC rubber duck antenna.

The two types of signal feedback in BWI Eagle systems are confirmation-only and true feedback.

Confirmation-only feedback tells you that the relay in the remote receiver is energized. Feedback is provided as a brief vibration or flashing LED on the handheld transmitter. A stationary transceiver feedback is typically a flashing LED. Confirmation-only feedback confirms the receipt of the signal. It does not ensure that the equipment is running or that an action has been completed.

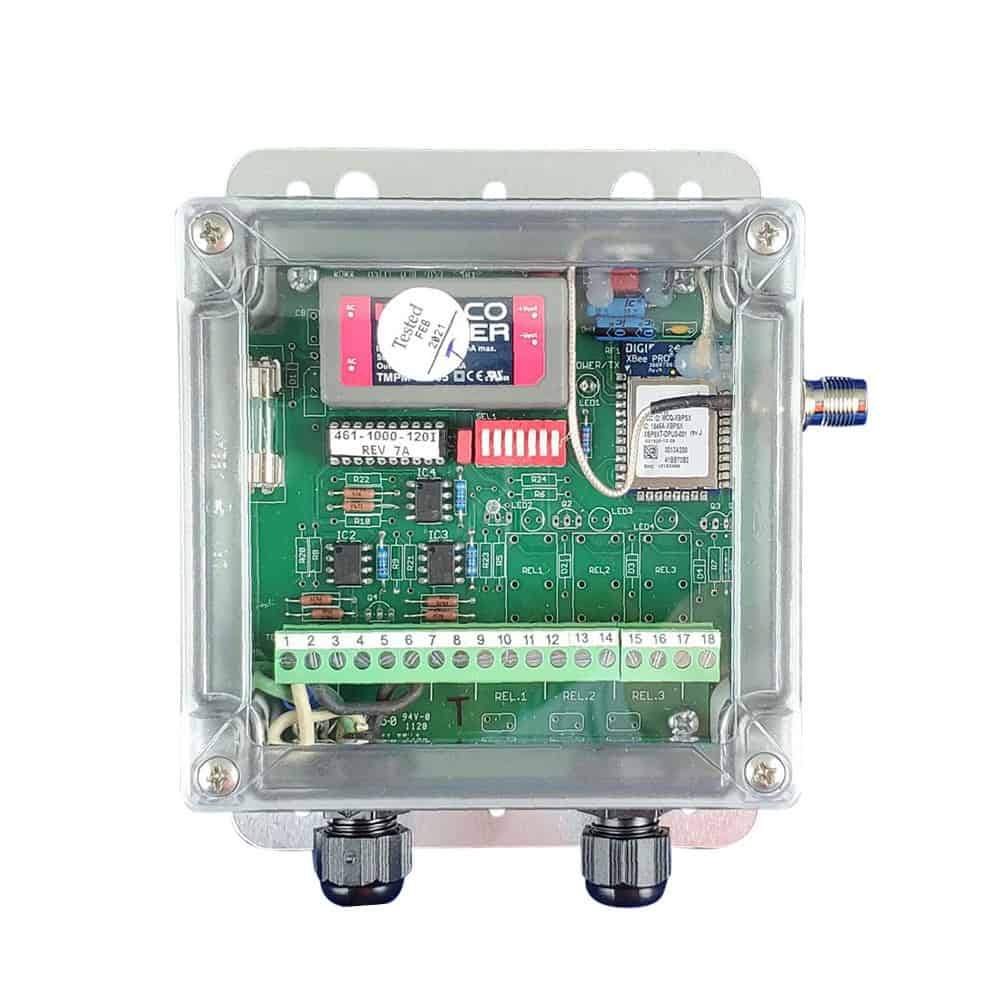

True feedback tells you that the remote receiver relay is energized and the equipment is running. Two transceivers are needed to achieve this type of feedback. Transceivers have both dry contact inputs and relay outputs. An input command from the control transceiver transmits to energize the relay in the remote transceiver. At the remote transceiver, a dry contact run input from the operated equipment is wired into the unit. When the equipment starts, it creates a closure on that input that automatically transmits back to the control transceiver and energizes the corresponding relay output. That relay output can drive any audible or visual indicator of your choice, thus letting you know the remote equipment has been actuated.

Some units have user-selectable digital addressing in addition to multiple frequencies. The default digital address on every BWI Eagle model is zero. All units have eight frequencies possible under the digital address zero. To add more than that, you would set the digital address of the next group of units to one. You then will have up to eight additional frequencies under digital address one. Each time you increment the digital address, you have up to eight additional frequencies. The user-selectable digital address models have 16 addresses. This means you can have up to 128 units operating side-by-side without interference.

Timed Relay Activation – Receivers can be factory programmed to have one or more relays automatically energize or de-energize after a specified period of time.

Dual Relay Activation – Receivers can be factory programmed to have one or more relays react to a single command.

Exclusive Relay Operation – Receivers can be factory programmed to have one or more relays automatically de-energize when another relay energizes.

Sequenced Relay Operation – Receivers can be factory programmed to have relays energize and/or de-energize in a sequenced manner.

Passcode Required – Transmitters can be factory programmed to require a “passcode” to be entered before the unit will transmit a command.

Enable Button – Transmitters can be factory programmed to require the operator to hold in an “enable” button while pressing any other button in order for the unit to transmit a command.